Asphalt

grey

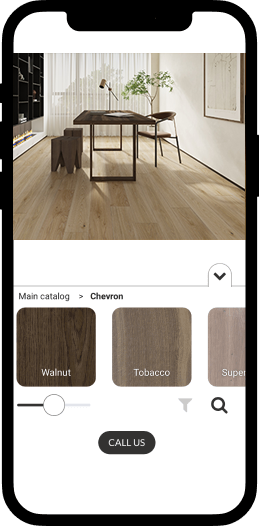

Išskirtinis, modernus dizainas, interjerui suteikiantis elegancijos ir prabangos dvelksmo. Ramios ir natūralios spalvos padeda kurti stilingą, jaukią ir malonią namų atmosferą.

Autumn

alyva

Grindys - vienas svarbiausių namų interjero elementų.

Tinkamai pasirinkus parketo raštą ir spalvą Jūsų grindys atrodys be galo įspūdingai!

Apie mus

Sveiki atvykę į „Staki“, kur klasikinę, aukščiausios kokybės ąžuolo medieną paverčiame išskirtinėmis jūsų namų grindimis. Tris dešimtmečius veikiančioje šeimos gamykloje daug dėmesio skiriame kokybei, tvarumui ir naujovėms, leidžiančioms ąžuolo grindimis mėgautis daugybę metų.

Išsirinkite geriausias grindis savo namams iš gausybės mūsų siūlomų atspalvių ir džiaukitės jomis visą gyvenimą.